GRAS 147AX CCP 坚固型压力场传声器

发动机噪声测试的新模式

客户对汽车降噪的期望越来越高。因此,原始设备制造商一直在努力识别和减少噪声源。此外,快速原型设计和缩短 "上市时间 "的压力越来越大,这就要求改进噪声、振动和声振粗糙度(NVH)测试方法并提高其效率。在这一过程中,生成可靠的数据至关重要,这就要求使用市场上领先的 NVH 测量传声器,并不断改进测量程序。

GRAS 147AX 坚固压力传声器经过专门设计,可在其他类型传声器难以触及的位置实现 发动机噪声测试 的可重复测量。

面临的挑战

发动机噪声测试包括声传递函数 (ATF) 测定。使用最广泛的是互易法,用胶水、胶带将大量自由声场标准 ½" 传声器固定在发动机上,或是安装在三脚架上。这种方法比较麻烦,非常耗时,而且由于设置难以复制,结果的准确性有限。

传声器定位不精确。

精确的重新定位几乎是不可能的。

传声器的自由声场特性与声场特性不匹配。

即使是微小的重新定位差异也会带来相当大的测量误差。

检测和调查特定的噪声源。

传统传声器很容易损坏。

许多原始设备制造商使用的传声器寿命很短,因此拥有成本很高。

进一步了解 NVH 测试挑战 以及如何选择合适的传声器。

发现优势

147AX 经过优化,能够承受发动机舱内的恶劣条件。它的安装简便且可重复,可获得高精度和快速的测量结果。147AX 传声器(专利申请中)具有实验室精度、与发动机舱内高温和恶劣条件相匹配的极端坚固性,以及新颖的外形和安装系统,注定会成为世界各地测试机构的首选解决方案。

坚固的设计

即使在恶劣的测试环境中,如试验场或公共道路上,也能获得准确的数据。

电源指示灯

开机时可视化确认状态和传感器电子数据表 (TEDS) 读数,确保数据采集的效率和就绪状态。

外形小巧

可用于传统自由场传声器必须放弃的狭小或难以进入的空间。

在线校准数据

每个特定传声器的校准数据可在 gras.dk/e-data上进行评估。

防水、防油、防尘,可更换栅格

可在污染环境中使用—过滤器更换简便。

耐高温

可安装在靠近热源的地方。

防水设计

传声器—前置放大器外壳(包括连接处)通过 IP67 防水认证。

坚固的电缆

减压和防水连接可确保数据完整性和户外测试期间的生存能力。用户可更换电缆。

受保护的通风装置

潮湿的环境不会影响测量。

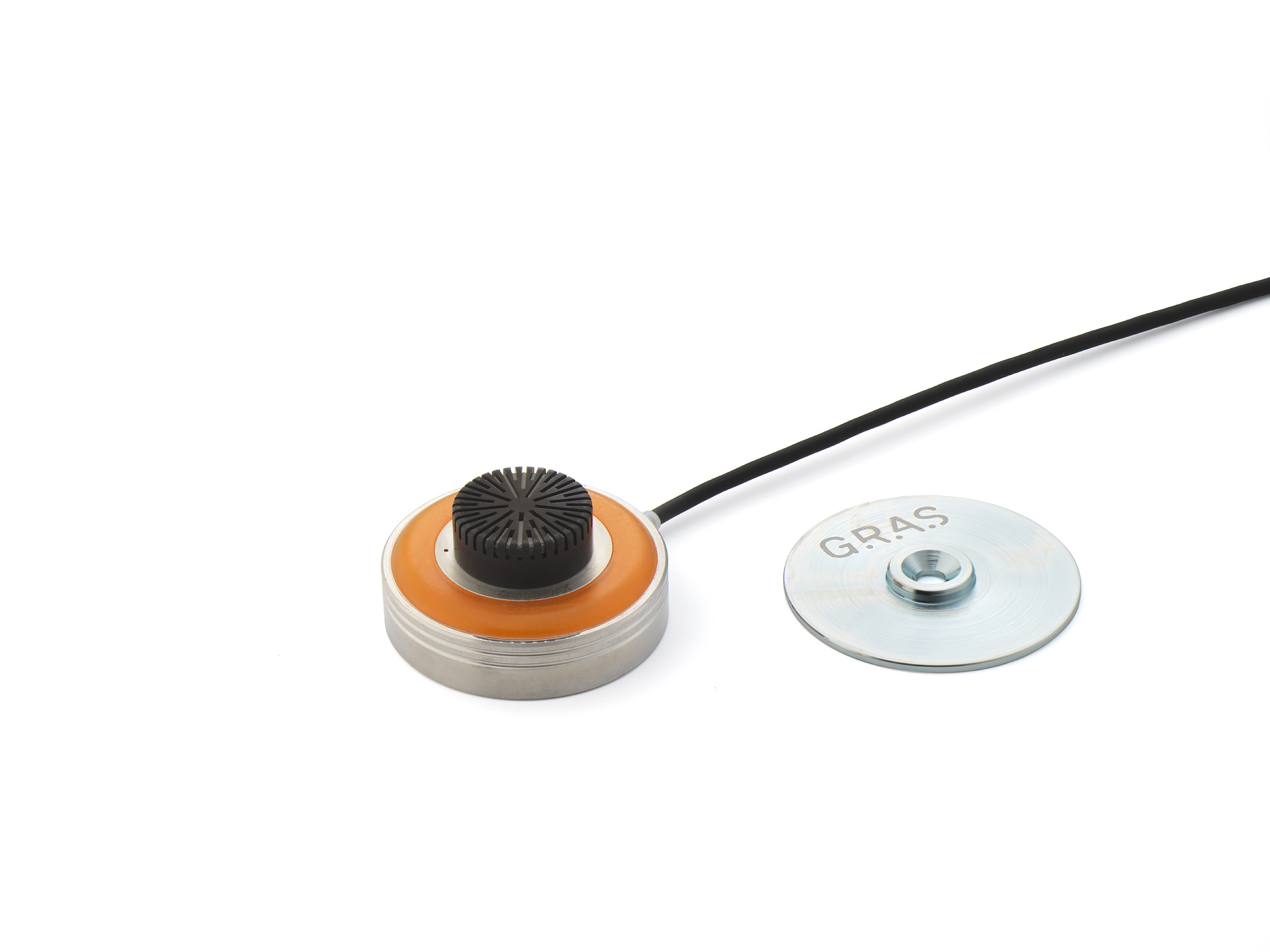

MagMountTM 安装系统

147AX 传声器外壳的背面有一个强大的内置磁铁,可以将传声器放置在任何平坦的金属表面,而不会影响测量。此外,还可以使用安装盘将其轻松固定在发动机舱内的任何位置,从而实现传声器的快速、精确和可重复安装,即使在狭窄的空间内也是如此。

重复安装和拆卸不会影响安装精度或测量的重复性。相同的安装点可用于冷态和热态发动机测试,包括在试车场或公共道路上进行测试。

147AX 表面安装传声器的栅格内置过滤器,只要过滤器堵塞,就可以轻松更换。安装盘可以用胶水、双面胶带或螺丝固定在测试物体上。

了解在进行发动机舱测试时如何安装 GRAS 147AX , 并了解我们在校准或执行其他技术维护时为 NVH测试提供的技术支持 。

如果您需要进一步帮助,请访问我们的 全球支持 网页.

频率范围:3.15 Hz - 20 kHz

动态范围:19 dB(A) - 133 dB

灵敏度:42 mV/Pa

温度:-40 - +125°C

湿度:0 – 90%

IP67

GRAS 147AX 是一款坚固的 CCP 表面安装式压力传声器,为汽车发动机舱测试进行了优化。它有一条带 BNC 接头的集成电缆,并配有一个全新的磁性安装系统,即使在难以进入的地方也能轻松而精确地安装。

Technology

Introduction

147AX is a rugged surface-mounted pressure microphone optimized for engine compartment testing in the automotive industry. It combines the high precision and stability of a laboratory microphone with a high level of ruggedness, including the ability to function properly in the most challenging environment with vibrations, oil mists, water spray and dirt and dust - and high temperatures up to 125°C.

With the 147AX it is now possible to introduce a considerable improvement in the way acoustic engine compartment measurements can be done. The small form factor makes it possible to place the microphones where size constraints previously prevented so. Also, the microphone system's resistance to heat, dirt, oil mists and vibrations makes it possible to make hot engine tests under real-life conditions. A novel mounting system (MagMountTM) makes it easy to mount precisely and ensures very good repeatability, even after full dismounting of the microphones.

Design

Like other members of the GRAS family of microphones for automotive NVH testing, the 147AX is designed to perform optimally under the rough conditions encountered in automobile NVH testing.

The most important design features to accomplish this are:

Vibration resistant and rugged

A new design of the preamplifier and other internal parts makes it resilient to shock and vibrations. It functions well under conditions with vibrations and g-forces from uneven road surfaces and other sudden directional shifts as encountered in real-life driving tests.

The most vulnerable part of any condenser microphone is the diaphragm. In the 147AX a more robust type is used. It can be replaced during repair, keeping maintenance costs at a minimum.

Temperature resistant

The microphone set works properly up to temperatures of 125°C/257°F. The integrated cable is a high-temperature type. This means that the 147AX can be mounted closely to heat-emitting components and will provide reliable data in all realistic use scenarios.

Effective protection

The microphone-preamplifier assembly is effectively sealed against moisture and is IP67 rated. Special protective water and oil repellent coating adds further protection and makes it easy to clean.

The microphone diaphragm is protected by a grid that has a comprehensive multi-layer filtering system that ensures good protection against high-velocity particles and prevents dirt and dust from polluting the microphone. Provided that the protective grid is replaced at appropriate intervals this system ensures that the microphone will function properly even in very dirty conditions. The filter also protects the diaphragm against water splashes and oil mists.

A customized windscreen is available. Even when turbulence is not a problem it can be used for further protection.

Robust cabling

A special connection system with added strain relief is used to provide a robust and watertight connection (IP67) and is sufficiently robust to endure the intended use scenarios. The cable can withstand temperatures up to 125°C/257°F and is oil resistant - if subjected to oil the insulation will not become brittle. The cable and its connection to the microphone are resistant to even heavy vibrations.

A number of cable replacement kits are available for user replacement of the cable. In this way, possible downtime is reduced.

Easy and repeatable mounting - MagMountTM

Compared to traditional, tube-shaped 1/2" microphone sets that are mounted with tape or holders attached to the engine and/or its auxiliary equipment, the 147AX is a surface-mounted microphone designed to be mounted on flat or slightly curved surfaces, for example on the engine compartment walls/boundaries. This normally requires mounting methods that make dismounting difficult and potentially destructive, for example, glue. Such methods can of course still be used, but the new magnetic mounting system called MagMountTM is much easier to work with and provides the basis for better measurement results.

The MagMountTM mounting system consists of a flat metal disc which functions as a mounting base for the microphone, and a magnet at the rear of the microphone housing. The flat metal disc is for mounting at the designated mounting point and can be secured with glue, double-sided bonding tape or a screw. Using the double-sided bonding tape delivered with the 147AX ensures an extremely strong mounting, but using glue may also be a good choice.

When the microphone is placed over the mounting disc, a center guide ensures that the microphone will be attached and centered to the disc correctly once the magnetic force kicks in. In this way, it is easy to mount in difficult-to-access locations with no loss of placement accuracy.

This mounting system makes it possible to mount and dismount the microphone repeatedly even in difficult-to-access spaces where you cannot see what you are doing. When a microphone is dismounted and later remounted, the difference between these two mountings will be only a fraction of a millimeter. In this way, variations in transducer position from test to test are minimized, ensuring very good repeatability even if all microphones have been dismounted between measurements. Also, transducer placement inaccuracies due to operator error are no longer a problem.

This system makes it easy to document how microphones have been placed during a given test, and it makes it possible to identify and prepare measurement positions at an early stage, e.g. before the room in which they will be used is finally assembled.

Combined with the 147AX's ruggedness - in this case, its ability to handle heat and vibrations - this also makes it possible to retain a measurement setup with the same measurement points, even when transitioning to hot engine testing and prolonged testing on proving grounds or public roads.

Even though the microphone will be firmly attached to a vibrating structure, this fact will not prevent proper operation. The microphone itself and all interior parts are designed to work correctly when vibrating. Furthermore, the diaphragm is extremely lightweight with a very small mass. This means it will not react to the vibrations in the same way as an accelerometer at the same location would. Below its resonance frequency at 18kHz, the low mass and high stiffness of the diaphragm reduce the influence of structure born vibrations. Even at the resonance frequency at 18kHz, the dampening is sufficient to prevent a peak similar to that found in accelerometers.

Compared to using traditional tube-shaped microphone sets attached with tape or holders, 147AX’s mounting method is much more stable AND less sensitive to vibrations.

Therefore, at the noise levels expected to be found in the engine bay, the 147AX provides a good signal-to-noise ratio even when mounted on a vibrating structure.

Small form factor

As a surface-mounted microphone, the 147AX can be used where a traditional 1/2" microphone set is too big. Low height allows for placement in difficult-to-access small cavities and near hard reflective surfaces, making it possible to install a microphone where a traditional ½” microphone set is too big to use. As modern engine rooms normally are densely populated this can be a major advantage.

This advantage makes it easier to define microphone placement and to have identical setups over a long time and across models to document the effects of changes. Also, it will often be easier to place microphones close to the individual noise sources that need to be investigated.

Pressure-field response

The 147AX is a pressure microphone. Where a free-field microphone is designed with a high-frequency roll-off to compensate for the effects of its own presence in the sound field, the response of a pressure microphone is flat. Therefore, when mounted at the boundaries of the sound field inside the engine compartment, a low-profile pressure-field microphone is the better choice, especially at high frequencies.

Windscreen

A special windscreen is available for 147AX and can be a viable option when it is placed in close proximity to airflow, e.g. a fan.

Integrated power LED for status indication

An integrated LED gives status information on power-up and checks, making it easy to verify that the microphone is ready to measure. If there is a faulty connection, the LED will not be lit during power-up. The LED will light up when the TEDS chip is read.

Benefits

The comprehensive precautions taken to make the 147AX immune to adverse test conditions result in a number of benefits that all translate into time saved and lower costs of ownership. The total life span of the microphone set will be many times that of a conventional microphone set that must be discarded due to damage from dirt, moisture, shock, and vibrations. Also, system and set-up related costs are minimized due to the precise and easily reproducible location of the microphones enabled by the MagMountTM mounting system that makes well-defined measuring points and highly repeatable measurements possible.

-

The 147AX is a pressure microphone. Unlike a free-field microphone, it will not underestimate the sound pressure in the pressure-field conditions inside an engine bay.

-

The same microphone set can remain mounted in a test configuration for extended periods of time or remounted very quickly.

-

Measurement points can be identified and described precisely.

-

Measurement setups can be recreated easily and precisely, ensuring very good repeatability between measurements.

-

Separate test results are immediately comparable because the same stable microphones are used at the exact same positions.

-

TPA and hot engine measurements can easily be compared.

-

The protection grid with its protective filters can easily be replaced, for example before dirt and oil mists are clogging the meshes.

-

The CCP (Constant Current Power) technology allows for a low cost per measurement channel.

These advantages mean that the 147AX not only ensures a low cost of ownership but will also contribute to speeding up the development process by improving the quality of your measurements and reducing set-up time, factors that translate into competitive advantages.

Compatibility

The 147AX requires a constant current of 2 mA and a BNC connector. Ready to use standard coax extension cable assemblies of various types and lengths are available. Waterproof, heat and chemical resistant extension cables are also available. It is IEEE 1451.4 TEDS v. 1.0 compliant. If your measurement platform supports Transducer Electronic Data Sheets (TEDS), you will be able to read and write data like properties and calibration data.

System Verification

The integrated PowerOn indication and the functionality of TEDS are very useful to determine which microphone is connected to which input channel. However, it is not a check of whether the microphone is within specifications or not.

For daily verification and check of your measurement setup, we recommend using a sound source like the GRAS 42AG Multifunction Sound Calibrator with the calibration adapter that is part of the delivery.

Calibration Data

Calibration Data for each individual microphone set can be accessed online via the serial number. In this way, you can easily download and configure your analyzer with calibration data. Accessible on-line are also correction data for the protective grid in a format that your analyzer can read at www.gras.dk/e-data.

GRAS HALT

When our R&D team develops a measurement microphone, it must undergo the most demanding tests to prove that it can withstand our customers' daily test conditions. Using a series of Highly Accelerated Lifetime Tests (HALT) we ensure that our microphones live up to the high quality and precision that our customers have come to expect and trust. Our HALT tests actively accelerate the lifetime of a microphone by simulating the handling and use it is exposed to in real-life situations. By stress testing to the limits, we have been able to optimize the design for robustness and stability.

Service, Warranty and Repair

When leaving the factory, all GRAS microphones have been calibrated in a controlled laboratory environment using traceable calibration equipment. Depending on the use, measurement environment and internal quality control programs we recommend that the microphone is recalibrated at least once a year.

We offer two kinds of calibration as an optional after-sales service: GRAS Traceable Calibration and GRAS Accredited Calibration.

GRAS Traceable Calibration is a traceable calibration performed by trained personnel under controlled conditions according to established procedures and standards. This is identical to the rigorous calibration that all GRAS microphones are subjected to as an integral part of our quality assurance.

GRAS Accredited Calibration is performed by the GRAS Accredited Calibration Laboratory that has been accredited in accordance with ISO 17025 by DANAK, the Danish Accreditation Fund. If you want a new microphone set delivered with an accredited calibration instead of the default factory calibration, please specify this when ordering.

All parts are manufactured and assembled at the factory in Denmark by skilled and dedicated operators in a verified clean-room environment. Our warranty against defective materials and workmanship is 5 years.

147AX is patented in Europe.

Specifications

GRAS HALT Test Parameters*

Humidity 90% | @40°C | 48 hours |

Drop - vertical, attached to 2 kg load | m | 1.5 |

Drop - tumbling 1 meter | times | 100 |

Vibration - horizontal and vertical | @8g | 60 hours |

IP rating** | IP67*** |

*For a short introduction to HALT, see the section "GRAS HALT" above

**International Protection Marking, IEC standard 60529.

***IP67: Totally protected against dust, protected against the effect of water of up to 1 m of submersion.

IP test according to IEC 60529:2013 performed by DELTA - a part of FORCE Technology, Venlighedsvej 4, 2970 Hørsholm, Danmark. www.delta.dk

Typical frequency response.

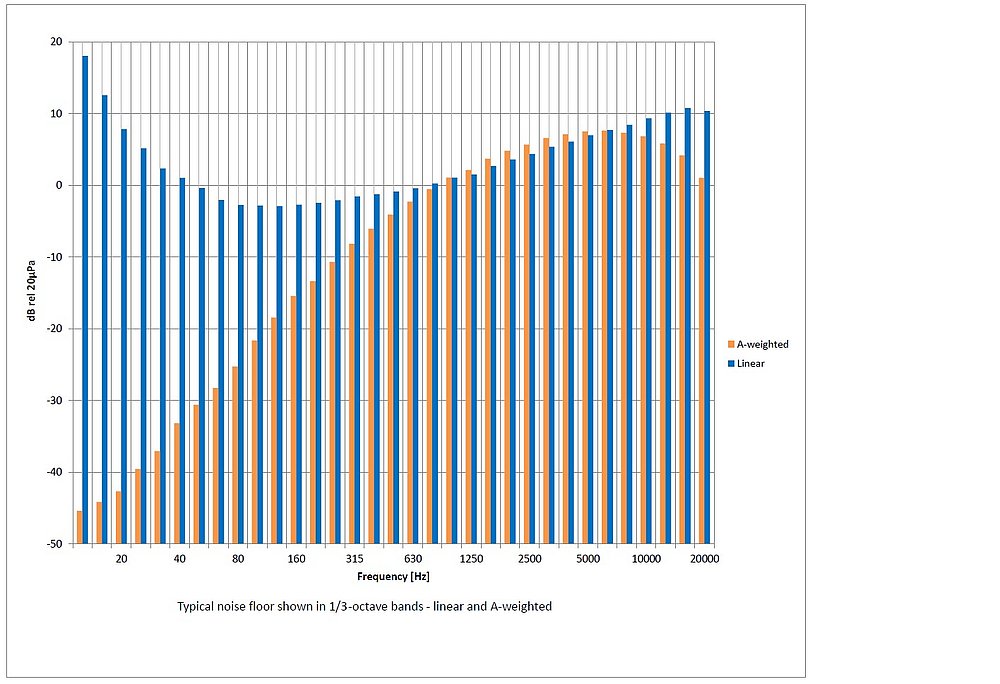

Typical noise floor.

GRAS Sound & Vibration 保留更改规格和配件的权利,恕不另行通知。

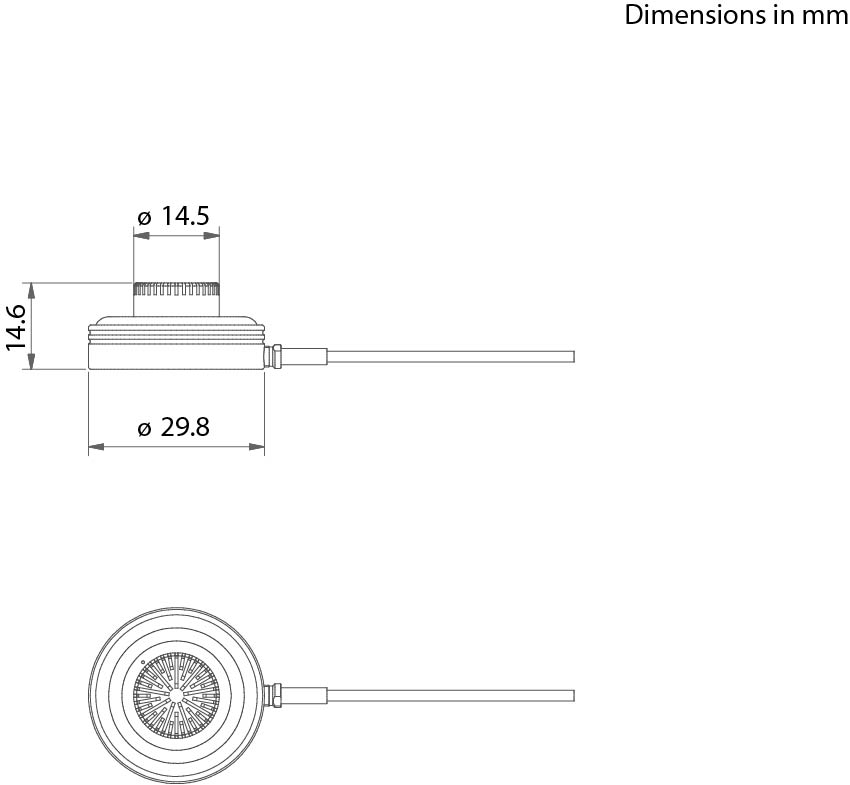

Dimensions

Ordering info

标配

| GRAS 147AX | CCP Rugged Pressure Microphone with 5m integrated BNC cable |

| GRAS GR2172 | Mounting Disc |

| GRAS RA0391 | Calibration Adapter for 147AX |

| GRAS DB0481 | Double-sided adhesive tape for mounting disc |

选配

| GRAS RA0390 | Dust, Oil, and Water resistant protection grid |

| GRAS AA0107 | 1 m waterproof/high-temperature BNC-BNC extension cable |

| GRAS AA0108 | 3 m waterproof/high-temperature BNC-BNC extension cable |

| GRAS AA0109 | 10 m waterproof/high-temperature BNC-BNC extension cable |

| GRAS RA0393 | Cable Replacement Kit, 5 m |

| GRAS RA0394 | Cable Replacement Kit, 10 m |

| GRAS RA0395 | Cable Replacement Kit, 20 m |

| GRAS RA0396-CL | Cable Replacement Kit, Custom Length, meters |

| GRAS RA0398 | Fairing for 147AX |

| GRAS AM0388-1 | Windscreen |

| GRAS AM0388-2 | Windscreen, 5 pcs |

| GRAS RA0392-1 | MagMountTM Mounting disc (5 pack) for 147AX, including double-sided adhesive tape |

| GRAS RA0392-10 | MagMountTM Mounting disc (50 pack) for 147AX, including double-sided adhesive tape |

| GRAS CA2300 | Accredited Calibration |